Wagners Composite Fibre Technologies (CFT) recently sat down with Magryn & Associates and Larcombe General Builders to discuss the design and construction of Admirals Arch on Kangaroo Island off South Australia.

Wagners CFT Business Development Manager for South Australia, Robbie Westley set the scene by describing Kangaroo Island as the jewel in South Australia’s tourism crown.

“Admirals Arch is located off the south-western tip of Kangaroo Island off the South Australian coast, which is just under 4,500 square kilometres and has a population of approximately 4,700 people. It is the second largest island in Australia,” Robbie Westley said.

“More than 200,000 people visit Kangaroo Island every year with approximately 120-thousand of those going to Admirals Arch and Remarkable Rocks,” Mr Westley said.

“More than a third of the island is protected nature reserves with pristine coastlines; there’s wineries, oyster farming, beautiful wildlife parks, many areas of cultural significance and numerous native flora and fauna attractions,” he said.

“Admirals Arch itself is a natural rock arch created by amazing forces of nature, and tourists access the arch via a set of stairs which go over a cliff face, leading down to a viewing platform where wild fur seals play amongst the rocks and pups can often be seen swimming in rock pools. It’s truly an incredible view and an amazing opportunity for tourists, on an international scale, to watch fur seals in the wild.”

Pictured – Admirals Arch is located on the south-western extreme of Kangaroo Island off the South Australian coast

There were numerous problems with the existing structure for asset owners, South Australia’s Department for Environment and Water (DEW).

“The existing timber structure had reached the end of its serviceable life; the timber was decaying in the harsh coastal environment and potentially starting to become a safety issue for the asset owner as well as a drain on resources with regular costly maintenance required to keep it open to tourists,” Robbie Westley said.

“Due to the remoteness of the site, it was a logistical nightmare to organise regular repairs and given the popularity of Admirals Arch, it was also extremely difficult to shut down the structure for repairs, especially during peak tourist periods.”

But with rising maintenance costs, increasing safety concerns and potential impacts to tourism, the asset owners made the decision to replace the existing structure and were very specific about their needs for the new structure.

“The Department of Environment and Water needed the job to be done quickly, preferably during tourism off-season or in a time that was not going to impact tourism to the site,” Robbie Westley said.

“They wanted to limit any impact to the environment during demolition of the old structure and installation of the new structure owing to the importance of the area to the fur seal and due to it also being in a National Park,” Mr Wesley said.

“Plus, they also wanted to ensure that the new structure was safe environmentally and wouldn’t leach horrible chemicals into the sensitive environment or shed micro plastics into the ocean,” he said.

“They wanted a structure that was going to be low maintenance and have a long service life and so they chose to replace the existing timber structure with Wagners Fibre Reinforced Polymer (FRP).”

Pictured – the old timber structure at Admirals Arch has reached the end of its serviceable life and was costing a lot of money in repairs to keep it open

South Australian based engineering consultants, Magryn & Associates were engaged to certify the design of Admirals Arch; Technical Director and Senior Engineer, Will Souter said the project’s challenging terrain and unique environmental needs were key aspects of interest for the business.

“Magryn is a medium sized engineering consultancy specialising in civil and structural engineering with a strong focus on coastal and maritime engineering; so we’ve got a particular passion for working on challenging projects in unique environments that deliver impactful results,” Will Souter said.

“At Magryn our vision is to help shape more resilient communities and infrastructure for the future by delivering engineering solutions that are future proof, ensuring safety and sustainability are embedded into the designs,” Mr Souter said.

“Our relationship with Wagners CFT has grown over recent years, and we’re proud to be one of their trusted Design Partners due to our expertise in Fibre Reinforced Polymer or FRP,” he said.

“Our experience designing with FRP has been tested on a variety of projects such as jetties, mooring facilities, boardwalks, beach access, stairs and ramps; and the Admirals Arch boardwalk is a great example of the type of project we strive to be involved with due to its unique location and challenges.”

Pictured – the terrain at Admirals Arch is very steep and rugged

Site geography would also test those working on the Admirals Arch project with steep uneven terrain and low to medium strength limestone sedimentary rock foundations.

“We were engaged by Wagners to undertake an independent engineering review and to certify their original design; so, we were also responsible for ensuring the as-built structure was installed as specified and all required design performance criteria and the intent were met,” Will Souter said.

“Just to summarise a bit of the background geotechnical investigation work that was done by FMG prior to construction; so, the site geology consisted of exposed limestone rock with a low to medium strength, and containing widespread cavities including large areas of undermining,” Mr Souter said.

“While much of the weathering of the weaker material had already occurred over many years, the limestone would continue to weather over time and over the long term and at the low level the geology was a harder bedrock; so, as a result of that the footing locations had to be carefully chosen and adapted on site to avoid weak or unstable areas,” he said.

Pictured – an example of where some localised collapse had occurred, and as a result careful design consideration and construction strategies had to be in place to mitigate the risks associated with ongoing weathering and to ensure stability of the structure over its lifespan

“So, some potential further geotech investigation was identified, such as detailed face mapping of the rock or core sampling to undertake testing. However, it was noted that this would not be very cost effective and would offer limited benefit to the new design so as a result, it was determined that the expertise of the structural engineer and the contractor would be relied upon to identify the footing locations, without the need for further extensive geotechnical investigations.

“That leads into the safety and design aspects and considerations of the project; so, when determining and finalising post locations of the new structure, each post was considered on a case-by-case basis.

“We did detailed case by case risk assessments, evaluated the potential for rock movement or weathering and where the risk was deemed too high, we made adjustments, whether that was relocating posts or introducing additional posts to spread the load more effectively and also add redundancy into the design.

“This approach helped us ensure that the boardwalk remains safe and stable throughout its lifecycle, even under these sorts of challenging conditions and changing conditions over time.”

Meanwhile, Magryn & Associates Design Engineer, Ahmad Ouban said FRP exhibits excellent resistance to corrosion and is incredibly strong relative to its weight, which makes it ideal for applications where weight reduction is critical.

“Despite being lightweight, FRP can exhibit tensile strengths comparable to or even exceeding steel in some fibre orientations,” Ahmad Ouban said.

“The site of Admirals Arch Boardwalk was characterised by steep and uneven terrain, and accessibility was limited, so the lightweight nature of FRP made logistics of construction a much smoother process,” Mr Ouban said.

“FRP is anisotropic which means that its mechanical properties such as strength and stiffness vary depending on the direction of the applied load,” he said.

“FRPs fibres are aligned in specific orientations, typically along the load paths, which makes it very strong along the fibre direction but weaker in other directions.

“This directional behaviour requires careful consideration and design, ensuring that loads are aligned with the fibre orientation. This is in contrast to steel, which is isotropic, and its mechanical properties are uniform under all load directions.

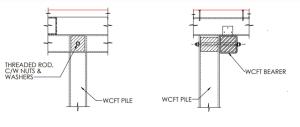

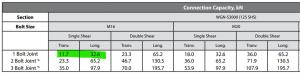

“The anisotropic nature of FRP also requires careful connection design. This is clearly shown in the table above, extracted from the Wagners Design Guide, where the differences in the shear capacity in the transverse and longitudinal directions is noteworthy.

“Another point of contrast between FRP and steel is ductility. FRP exhibits limited ductile behaviour, meaning if FRP members were to fail, the member will display little warning up until the failure of the member.

“Instead of FRP yielding under load, it tends to behave elastically up to a certain point, and then fails suddenly. The lack of plastic deformation necessitates a conservative design with higher safety factors, which is accounted for in the Wagners’ Design Guide.

“When overloaded, FRP may fail in a number of ways, including fibre rupture and crushing, which is characteristic of hollow FRP sections. Fibre rupture occurs when the applied tensile stress exceeds the strength of fibres, leading to failure of the fibres and subsequent failure of the member.

“Crushing of an FRP member may occur under high concentrated, or bearing loads, especially in hollow sections; this necessitates the use of anti-crush inserts to prevent crushing of FRP hollow sections subjected to high concentrated or high bearing loads.

“This can occur where FRP hollow sections have been bolted, and the bolted connections are under high tension, resulting in deformation of the hollow section, thus requiring anti crush inserts.

“The unique topography of Admirals Arch called for unique solutions to be implemented to provide adequate support to parts of the structure and an example of this is the use of FRP hollow members to support bearers directly onto rock, with anti-crush inserts to protect the hollow FRP profiles from crushing.

“Where feasible, the footings of the original structure were used to maximise efficiency, despite not being in accordance with the original drawings, the moment capacity of piles embedded into rock likely met or exceeded the moment capacity or baseplates and chemical anchors used on other parts of the structure.

“The challenging topography of Admirals Arch called for some adjustments during the construction phase to accommodate the irregular and steep terrain and provide additional support to the structure where the underlying rock was unsuitable for post supports.”

Pictured – The differences in the layout of the actual and design structure are shown on the overlay of the as-constructed survey onto the original design drawings

Another challenge that emerged during the construction phase of the project was providing adequate base plate support in the steep terrain.

“It was a specific requirement from the Department of Environment and Water (DEW) that breakage of rock be minimised to preserve the site’s natural state, hence the breaking out of rock to provide a stable platform for baseplates was not possible in most cases,” Ahmad Ouban said.

“Consequently, this led to some base plates being positioned on very steep sections of the cliff or rock, and the grout pad being built up to 500 millimetres in some instances, which made these grout pads non compliant with the manufacturer specifications and original Wagners’ design drawings,” Mr Ouban said.

“To address this, where the height of the grout pad exceeded 100 millimetres, thus requiring a solution in collaboration with Larcombe Builders and DEW, we came up with the idea to reuse the remaining Wagners deck mesh to provide confinement to the grout pad and to minimise the effect of erosion on the grout pads over time,” he said.

“Chemical anchors were fixed into the rock and the deck mesh was tensioned to the exposed bases of the grout pad to prevent blowout of the grout pad under load.

“The grout pads were not designed to exceed 100 millimetres in thickness, so this solution provided a degree of reinforcement to the raised pads. This was a satisfactory outcome for all parties, because the materials did not have to be sourced from outside of Kangaroo Island, which may have been costly, and the solution was implemented within the time frame of the project.”

Pictured – Reinforced grout pads used to counteract the steep undulating terrain of the Admirals Arch site and environmental limitations on drilling the limestone foundations

Kangaroo Island based business, Larcombe General Builders were appointed to construct Admirals Arch, and Construction Manager, Jake Nolan said it was a very interesting project with lots of complexities.

“Timing was the first major challenge that we encountered on the Admirals Arch project,” Jake Nolan said.

“Admirals Arch is located on the far western extreme of Kangaroo Island and so this area and this structure cops the full brunt of weather from the Southern Ocean; and it was this extreme weather that we needed to consider in the timing of this project,” Mr Nolan said.

“The area is also very remote, with the majority of the island’s infrastructure on the other end; so there’s no Bunnings around the corner and everything needed to be meticulously planned and packed to maximise our time on site,” he said.

“With 60% of tourists to the island coming to see Admirals Arch, it was imperative that upgrades to the structure didn’t impact the tourist dollar or their experience through the area.

“Plus, with winter too dangerous for us to work on site, the decision was made to build during peak tourist season, which is January through to April, but to limit the impact on tourism through a sectional staggered build.”

The planning and logistics of deconstructing the old timber stairs and boardwalk and simultaneously building the new structure was the next big challenge.

“We worked with the Department for Environment and Water to come up with a strategy whereby we sectioned off an area of the old timber structure that could stay and continue to service the tourists while we constructed the new structure; this included a traffic management plan and directional signage, together with cordoned off areas to ensure the safety of public to access agreed areas,” Jake Nolan said.

“We also employed specialised machinery to minimise the impact on both the public and the existing structure. This included a 1.2 tonne mini articulated loader which we modified to include wider wheels so the weight of the machine was dispersed over the existing boardwalk to access the site,” Mr Nolan said.

“This little machine carried all the materials from the top of the car park to the first material holding zone. It was also used to remove all of the old material that was palletised and taken off site and out of the National Park for disposal,” he said.

Pictured – Circled at the top right of the picture is the zip line which Larcombe used to transport all materials to and from the site

“So staging was also a challenge for us at Admirals Arch because the boardwalk and stairs go over a cliff face and then return back on itself to the first viewing platform which looks out to the Southern Ocean; so as you can imagine, it’s very exposed, very narrow and the prospect of carrying down the equipment over this cliff was a big logistical challenge, which was just was not feasible to do by hand.

“DEW had also outlined in the contract that helicopters were not an option due to an osprey nest located nearby Admirals Arch. The eastern Osprey is an endangered species with an estimated 50 breeding pairs left along the South Australian coastline, so protecting that nest and making sure it was not disturbed was paramount.

“So we set up a zip line from the first material holding area just down from the carpark and this enabled us to get materials down to the actual construction area which was approximately 35 metres long and this was right amongst the territory of a fur seal colony.

“So in in the early part of this project, it was breeding season, and we had to have spotters watching for the fur seals, because the males can get very aggressive; and later in the project when the weather turned poor and the pups had arrived, we needed to be vigilant of the mothers that were protecting their young and those seals just looking to get out of the rough weather by sheltering up under the viewing platform itself.

“The geology of the site presented further challenges with the rock connections or the footings a mix of direct and embedment into limestone so when we removed the existing structure, we were left in some places with a very good footing that we could then embed direct into the limestone.

“In other areas this was particularly difficult because of the uneven and sharp drop offs of the rocks and in these spots the excessive confinement of the grout that was required for the footing was a big challenge that we had to overcome.

“This was one of these challenges on the project where it could have become a massive hold up and with these grout pads and stainless steel studs we delivered the outcome to satisfy the engineers. So together, working with the engineer and the client, this was a very good outcome to keep this project timeline moving forward.

Pictured – The new structure at Admirals Arch constructed from Wagners Fibre Reinforced Polymer (FRP)

The natural attributes of FRP also added value to the speed and ease of construction.

“There were a number of benefits from working with Wagners FRP on this project including because it’s lightweight; we were able to utilise the 1.2 tonne loader and zip line to get the materials onto the site. We didn’t require heavier, big machinery or tools to do the job,” Jake Nolan said.

“Also owing to its modular nature we were able to employ the staggered sectional build approach, plus we were also able to pre-fabricate the balustrades and handrails in house at our workshop in Stokes Bay, but then transported these to site for fixing in place. This reduced our team’s time on site, especially towards the end of the project where the weather was declining and we were coming into winter,” Mr Nolan said.

“The flexibility of the bulk supply of materials enabled us to make small yet critical modifications that were necessary to meet the structural demands of the terrain; we had to make adjustments in three specific locations to ensure that the structure met its design requirements on site,” he said.

“Because FRP will not rot, rust, or corrode, it is perfectly suited for this environment which cops the full brunt of the force of nature from the Southern Ocean. It is also totally exposed to the effects of sun and Wagners coating ensures that this structure has a long life despite its exposure to UV.

“It has a 100 year design life so I don’t think I’ll be back anytime soon to replace this structure and given that we’re locals and part of the community of Kangaroo Island we look forward to the tourists of the area and the locals alike enjoying this amazing natural wonder of Admirals Arch for decades to come.

To watch the full webinar on Admirals Arch visit https://youtu.be/DPqGNd_VlHw

To get a copy of Wagners Design Guide